What Are You Looking For?

Why do water-based defoamers need thickeners?

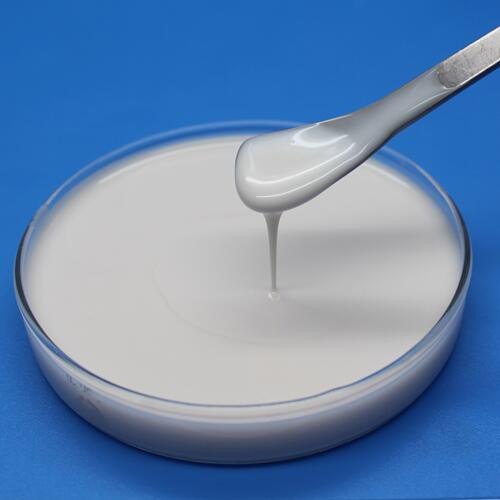

Jul 09, 2024The emulsions in many water-based defoamers are not very stable. To stabilize the emulsion, a small amount of thickener is added. When the defoamer solution is too dilute, using a defoamer thickener can save costs, so many manufacturers have used it.

How should we choose a suitable thickener for the defoamer? It is recommended to choose according to the following characteristics.

1. A thickener with good stability should be selected. Some thickeners are conducive to thickening at the beginning, but after a period of time, they show their true colors - liquefaction, which is what we call stratification or demulsification in the industry. Water is water, and the emulsion is an emulsion, which seriously affects the quality of the defoamer.

2. Choose and use thickeners with good dispersibility and compatibility. Some thickeners are extremely difficult to use. They need to be added to the water in an appropriate amount and dissolved for a long time before they can be used, which wastes time. Some powdered thickeners are not stirred well, and agglomeration will occur, which seriously affects the quality of the product. Therefore, it is best to choose a thickener that is easy to use and dissolves and thickens quickly.

3. Choose a thickener with stable quality. Some thickeners themselves have very unstable quality. One batch may thicken, and another batch may differ greatly, which will be seriously affected when used.

After meeting the above requirements, then consider the cost-effective thickener. Some thickeners are cheap, but the amount added is large and the cost of use is high. Some thickeners are more expensive, but the amount added is small and the effect is good,and the cost of use drops a lot. In fact, there is no best thickener, only the most suitable one.

Summary:

We should only choose the most suitable thickener to help thicken our water-based defoamer, thereby improving the stability, appearance and quality of the defoamer.

Tags :