What Are You Looking For?

Classification and characteristics of defoamers

Jun 07, 2024Defoamer, also known as antifoaming agent, is a chemical substance specially used to control bubbles generated by liquid surfactants. Defoamers can be divided into many categories according to their chemical composition and physical properties.

The following are several common types of defoamers and their respective advantages and disadvantages:

1. Silicone Antifoam: The main component of this type of defoamer is silicone.

Advantages: Silicone defoamer has excellent defoaming effect and can adapt to various solutions and systems. In addition, it also has good heat resistance, acid and alkali resistance and chemical stability.

Disadvantages: Although silicone defoamer has excellent performance, it is expensive, not easy to biodegrade, and may have a certain impact on the environment.

2. Polyether Antifoam: This defoamer is composed of polyether compounds and surfactants.

Advantages: Polyether defoamer can remain stable under high temperature environment, has excellent surface tension reduction effect, and is very suitable for high temperature defoaming needs.

Disadvantages: In some solvent systems, polyether defoamers may not be stable enough, and the right formula must be selected to achieve the best effect.

3. Fatty Alcohol Antifoam: This type of defoamer is often used for defoaming needs of oily media.

Advantages: Fatty alcohol defoamers are mostly extracted or synthesized from natural substances, are environmentally friendly, and have strong biodegradability.

Disadvantages: Although fatty alcohol defoamers are environmentally friendly, their defoaming effect is relatively weak and their scope of application is relatively limited.

4. Mineral Oil Antifoam: This type of defoamer is mainly made of petroleum derivatives.

Advantages: Mineral oil defoamers are cheap, easy to obtain, and have good defoaming effects on certain systems.

Disadvantages: Mineral oil defoamers are prone to adverse reactions with other chemicals and have a greater impact on the environment.

5. Antifoam Compound: This type of defoamer is a mixture of multiple different ingredients.

Advantages: Composite defoamers combine the advantages of various defoamers, improve the defoaming effect, and are especially suitable for complex defoaming needs.

Disadvantages: Due to the high cost, it is necessary to ensure the compatibility and stability between the ingredients.

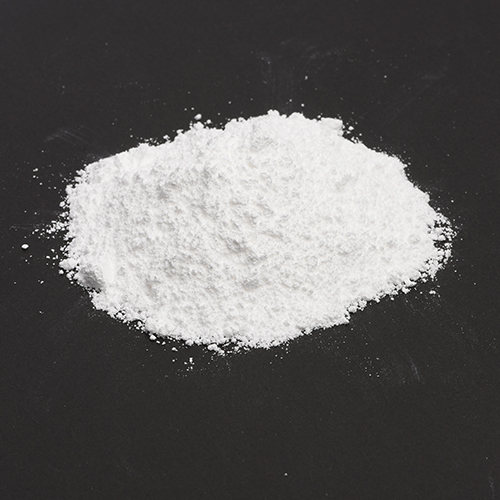

6. Powder Antifoam: This type of defoamer exists in solid form and is usually sold in granular or powder form.

Advantages: Powder defoamers are easy to carry and use, and can provide long-term defoaming effects.

Disadvantages: It may take some time to dissolve, so it is not suitable for all occasions that require instant defoaming.

Please note that each antifoam has its specific application field and process flow. Choosing a suitable antifoam requires comprehensive consideration of the specific application environment and needs. Before using a defoamer, please read the TDS and MSDS carefully, and conduct experiments and evaluations based on actual conditions.